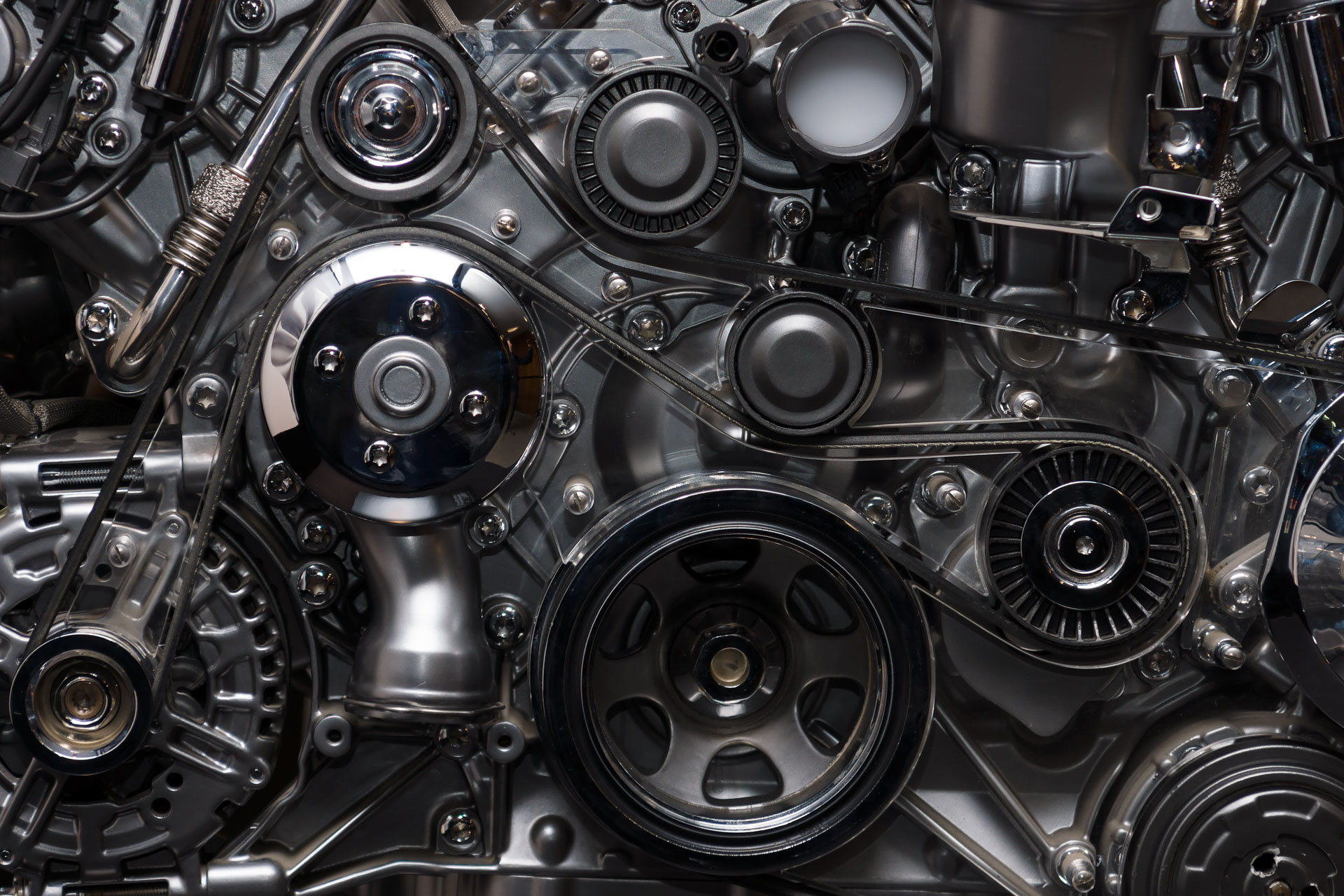

Eliminating defects and preventing failures is crucial to controlling variation, which refers to any deviation from an agreed standard. Precision maintenance helps maintain equipment to the highest standard possible, ensuring accurate machinery health from the start. EMS Precision Maintenance Services offers a range of corrective services, including laser alignment, oil and vibration analysis.

Stop Failures Before They Start

Protect your critical machinery and boost reliability. EMS Precision Maintenance’s advanced Vibration Analysis detects hidden problems like imbalance, misalignment, and bearing wear early, preventing costly breakdowns and unplanned downtime.

Why Choose Our Vibration Analysis?

We Monitor Your Critical Assets:

Proactive Maintenance. Precision Results. Gain peace of mind knowing your rotating equipment is monitored for early signs of trouble. EMS Precision Maintenance helps you move from reactive fixes to reliable operations.

Precision for Rotating Assets

The Problem – Unbalance caused by corrosion, wear, distortion, deposits, faulty assembly, or modifications leads to vibration, premature wear, and failure.

The Solution – On-site (“in-situ”) or in-shop dynamic balancing.

Key Advantages

Precision for Peak Performance

The Problem – Misaligned rotating machinery wastes energy, increases wear, reduces lifespan, and causes unplanned downtime.

The Solution – Precision alignment by trained technicians.

Key Benefits:

AHU Motor or Fan Failing? Get Fast Fixes. Stop downtime, noise, and high energy costs. Expert 24/7 repairs to restore airflow and efficiency.

Key Repair Capabilities:

At EMS, we combine technical expertise with real-world solutions, providing transparent diagnostics and prioritising your operational schedule. Our work isn’t complete until your system runs quieter, cleaner, and more efficiently

Your route to EMS Support & Maintenance Solutions. We’d love to hear from you!